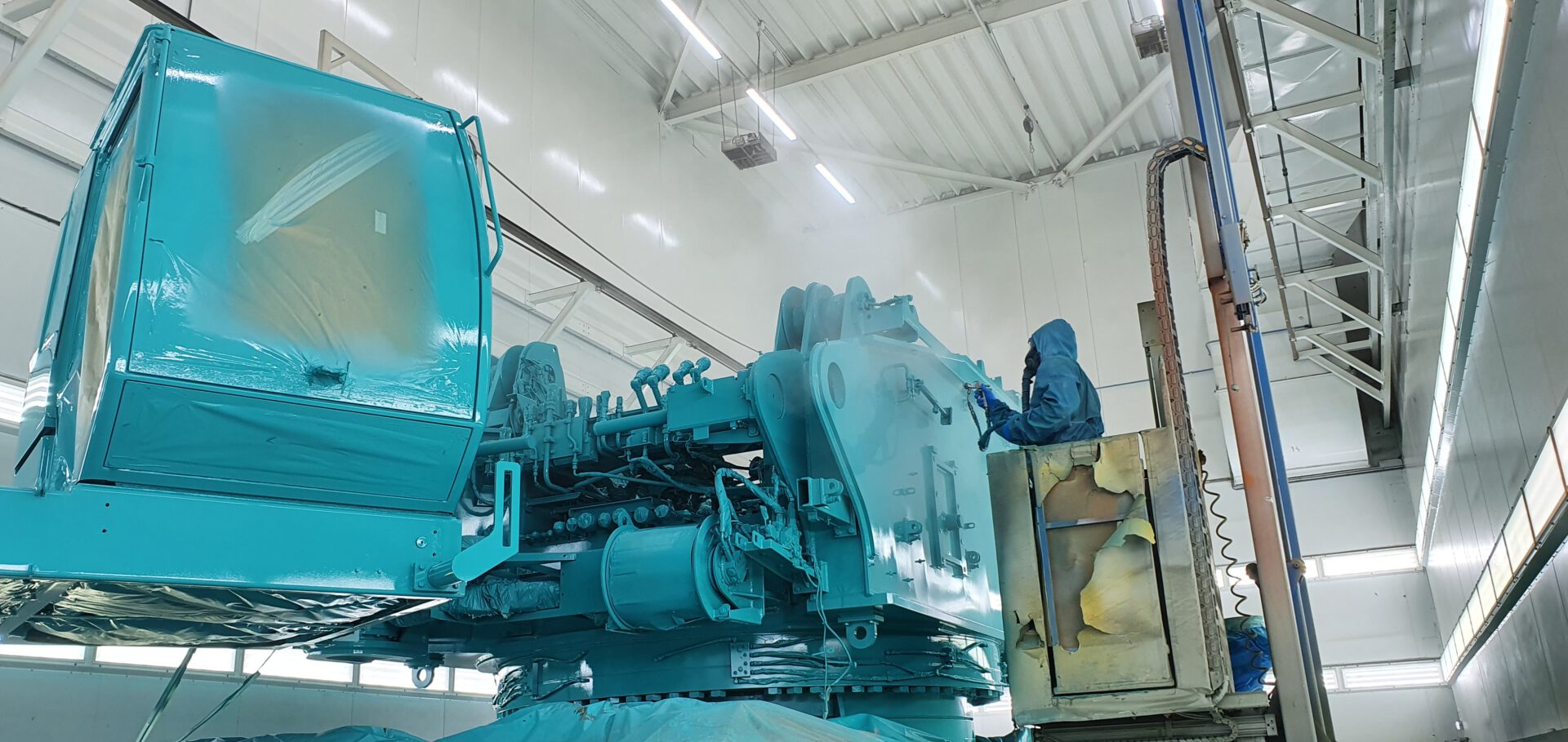

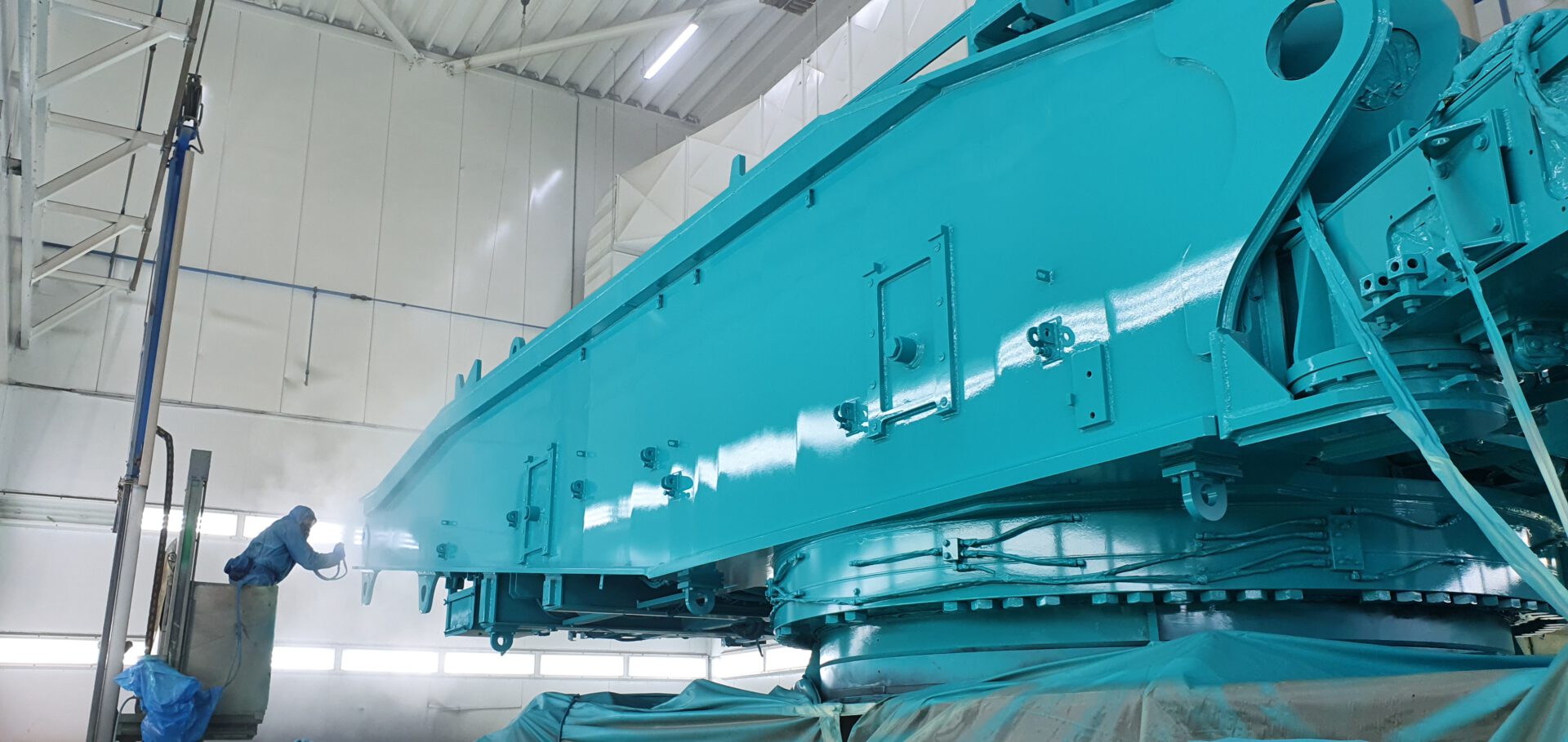

In our paint shop we have extensive experience in professionally painting Kobelco cranes. All our painting processes for Kobelco cranes are carried out at our facilities in Emmeloord. Our professionals have the necessary expertise and use the latest technologies to paint Kobelco cranes.

The painting of Kobelco cranes

The painting of Kobelco cranes

Kobelco about Gouweleeuw:

‘We regularly have cranes painted by Gouweleeuw. As a crane manufacturer, we commit to delivering top quality. By using a painter like Gouweleeuw, we can guarantee our top quality and we also opt for certainty. Agreements are strictly fulfilled.

For the painting of the 600-tonne Kobelco SL6000J, it was particularly important for us and for our customer that the entire process would run perfectly, as the crane had to be deployed for projects in the Northern Arctic as quickly as possible. In addition, the machine had to be extra well preserved against the extreme climatic conditions at sea in the Arctic working area. By applying a special epoxy paint to the machine and boom parts, the crane will be well and long-term protected against these extreme working conditions. The crane was delivered on time and we are very satisfied with the end result!’

Are you curious about the working process of the Kobelco SL600J? Then be sure to watch the video!

Working process of painting Kobelco cranes

Disassembly: We start with a partial disassembly of the crane. During this process we carefully check for rust and oxidation spots. If necessary, we treat these areas thoroughly for the best results. The sheet metal of the Kobelco crane is prepared and sprayed separately to ensure an optimal finish.

Cleaning: After disassembly, the Kobelco crane undergoes a thorough cleaning in our specially equipped washing area. This area has a maintenance pit and a platform, so that both the top and bottom of the crane can be properly cleaned.

Preparation: When the crane has been cleaned, the sanding process follows. The old layer of paint is removed and parts that should not be sprayed are carefully masked. If necessary, we treat any rust formation in this phase.

Working process of painting Kobelco cranes

Spraying: After the preparation work, the Kobelco crane is put into the spray booth. First we apply a primer layer and then we spray the desired paint layer.

Assembly: When the Kobelco crane has been painted, it goes to Assembly. The crane is fully assembled there.

Lettering and finishing touch: Upon request, lettering can be applied to the Kobelco crane in collaboration with Van Essen Van Raay (VEVR). The crane undergoes a thorough quality control to ensure that it meets the Gouweleeuw standard. Once the Kobelco crane is completely ready, it will receive our quality sticker as a finishing touch.

Request a quote free of any obligation

Are you interested in having Kobelco cranes painted by Gouweleeuw? Via this page you can request a quote easily and without obligation.

Contact us! +31 (0)527 252307

Short lead times

Safe and careful

Available 24/7

Full service paintshop

-

DisassemblyEach treatment starts with the disassembly of the machine. Large and heavy parts as well as small parts, whether or not equipped with electronics or hydraulics, are disassembled separately.Read more

-

CleaningEach part is thoroughly cleaned by means of various cleaning techniques in combination with specific degreasers.Read more

-

RepairsIs your object damaged? Or does it have a technical malfunction? Not to worry, our technicians will fix it.Read more

-

PreparationThis process is one of the most time consuming and important processes.Read more

-

BlastingBlasting is a very effective way to remove rust. We blast with the help of a blasting robot that makes the heavy blasting work lighter.Read more

-

Flame galvanisingFlame galvanising is the application of a zinc-aluminium layer on steel.Read more

-

CoatingImmediately after blasting, a chromate-free two-component epoxy primer-surfacer is applied, which guarantees good protection against rust formation.Read more

-

PaintingAfter preparation, a chromate-free two-component epoxy primer-surfacer is applied, which guarantees good protection against rust formation.Read more

-

LetteringAs a result of extensive experience in the field of decals, each object is provided with the desired corporate image.Read more

-

Finishing TouchYour machine is ready to be returned to you. But first the finishing touch:Read more